HEADING MACHINES

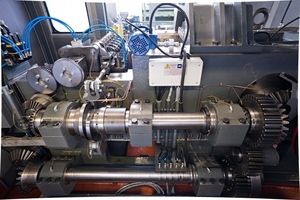

Precision is guaranteed by the dimensions of the lateral and support slides, built in the aluminum-bronze, which allow proper tolerances between the sliding surfaces.

The movement of the Transfer is realized through conjugated cams studied for smooth movements, especially during the phase of introduction of the pieces in the dies.

The opening of the fingers allows the extraction of the dies without the need to lift the transfer, thus allowing the conformation of large diameter heads.

Due to its design, even at reduced speeds, the press is able to forge parts with high precision. This is an advantage when it comes to parts that are difficult to transport or made of stainless steel.

Another advantage is that the flywheel is not mounted directly on the crankshaft (as in Chinese designs) but on another reduction shaft. This reduction is 1/4, that is, the flywheel has 4 turns to recover the energy used in the pressing. An advantage over the design of Chinese machines where the flywheel must recover turn after turn.

Varying the times allows to produce extremely difficult pieces and, in some cases, unique pieces that could not be made with ordinary machines.

The length of the principal slide, combined with the sizes of the guides, guarantee an excellent tolerance.

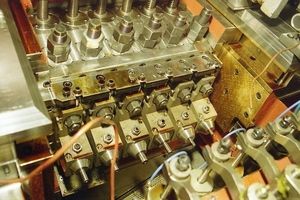

Lubrification is continuous and at high pressure (60-80 bar). This pressure ensures a constant oil film on the moving parts (connecting rod bushing, lateral and vertical slides, which in turn is an additional help to ensure the accuracy of the press.

The minimum length under the head theoretically does not exist, it is determined only by the minimum length of cut, expanding the range of achievable pieces.

Pneumatic trimming can be done in the last two stations, with ejection of the cut part behind the punch. The extraction shafts can be pushed from the behind or from the front (in the direction of the punches) depending on customer needs.

A gear motor is applied at the top of the wire to adjust the cutting length of the blank. Another gear motor allows the fine adjustment of the tools, without the use of the main motor (less energy consumption).

The cut-off system is straight, without intermediate parts, thus improving the sturdiness of the assembly.

Commercial parts are widely used in the project, which ensures a lower end cost and makes it easier for the customer to find spare parts in the market.

Maintenance is extremely simple and ergonomic. All moving parts are external to the machine's body, making access easy and intuitive.

| Model | N. dies | Φ wire | Ejection max | Φ dies | Φ punches | PKO | PPM | Blank | Tons |

|---|---|---|---|---|---|---|---|---|---|

| ST 040 | 4 | 10 | 75 | 60 | 50 | 25 | 210 | 105 | 95 |

| ST 050 | 5 | 10 | 75 | 60 | 50 | 25 | 210 | 105 | 105 |

| ST 150 | 5 | 14 | 125 | 70 | 60 | 30 | 160 | 160 | 130 |

| ST 160 | 6 | 14 | 125 | 70 | 60 | 30 | 160 | 160 | 130 |

| ST 170 | 7 | 14 | 125 | 70 | 60 | 30 | 160 | 160 | 140 |

| ST 240 | 4 | 19 | 180 | 100 | 80 | 45 | 110 | 230 | 230 |

| ST 240 l | 4 | 19 | 250 | 100 | 80 | 45 | 90 | 300 | 230 |

| ST 250 | 5 | 19 | 180 | 100 | 80 | 45 | 110 | 230 | 230 |

| ST 250 l | 5 | 19 | 250 | 100 | 80 | 45 | 90 | 300 | 230 |

| ST 260 | 6 | 19 | 180 | 100 | 80 | 45 | 110 | 230 | 250 |

| ST 260 l | 6 | 19 | 250 | 100 | 80 | 45 | 90 | 300 | 250 |

| ST 340 | 4 | 27 | 160 | 140 | 120 | 55 | 120 | 220 | 550 |

| ST 340 l | 4 | 27 | 300 | 140 | 120 | 55 | 80 | 360 | 550 |

| ST 350 | 5 | 27 | 160 | 140 | 120 | 55 | 120 | 220 | 600 |

| ST 350 l | 5 | 27 | 300 | 140 | 120 | 55 | 80 | 360 | 600 |

| ST 360 | 6 | 27 | 160 | 140 | 120 | 55 | 120 | 220 | 600 |