MACHINES RETROFITTING

Retrofitting of heading machines becomes necessary when the machines already show a lot of wear, or to adapt to safety standards, which are becoming more and more demanding.

The most common retrofitting (best cost-benefit ratio) is the one that takes the equipment to new mechanical conditions, without importance for aesthetics, painting and cabin that, normally, remain intact; obviously the machine is completely disassembled, cleaned and mechanically repaired. Productivity does not change in relation to the complete retrofitting, but we have a reduced cost, customers need a productive heading machine more than a beautiful one.

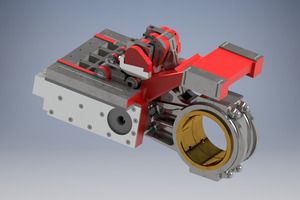

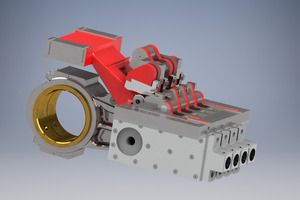

The third type of retrofitting is the revision of the core elements: principal slide, lateral slides, upper and lower, and when necessary, depending on the model and brand of the machine. The crankshaft and the connecting rod bushings are also worked on.

Another customized option is the transformation of the extraction transfer groups, adapting the existing heading machine to the customer’s purpose.

All interventions are budgeted and adjusted in advance before the start of the retrofitting, so the customer knows exactly how much he will spend to complete the retrofitting. In rare cases, non-budgeted items need to be replaced and many times they are only detected when disassembling the machine. Before any intervention, the customer is notified and the decision is always taken together.

Com um know how de mais de 70 anos, we offer our customers a unique service in the field of heading machines.

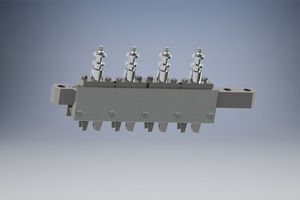

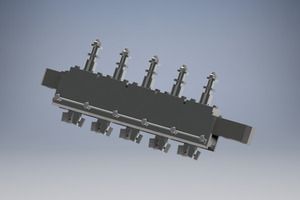

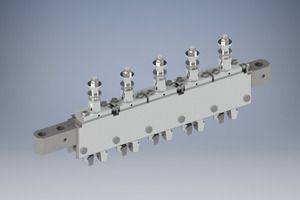

Spare parts are available for many brands of heading machines. If the drawing is not available, the parts can be designed and manufactured in a short period of time. Below are photos of several examples.